ProMach est votre partenaire du début à la fin. Nos marques de produits sont regroupées en secteurs d'activité distincts qui ont le plus de sens pour nos clients, couvrant toutes les fonctions de la ligne d'emballage: remplissage et bouchage, flexibles, manutention des produits, étiquetage et codage, fin de ligne et pharmaceutique.

Pour en savoir plus- Page d'accueil

- Produits

- DS Optima PH – Compact-Size, Cost-Effective, Pre-Configured Full GMP Washing Machine

DS Optima PH – Compact-Size, Cost-Effective, Pre-Configured Full GMP Washing Machine

Based on a list of items to be cleaned provided by the client, and using long-term experience, Steelco prepare a 3D model of the proposed rack. All items are grouped/organized per rack to optimize processing to fit production needs, in collaboration with the client user and production teams. Detailed design assures consistent water flow and pressure at all the internal and external surfaces of all the items to be processed, assuring repeatable, validatable cleaning. Rack design can

include: jets, nozzles, spray balls, tubing carousels and spray arms as needed.

A wide range of transfer systems are available both for DS part washer or LC floor loading cabinet washer:

- Fix height transfer trolleys in ASI 304 or ASI 316L

- Transfer trolleys with automatic lifting in ASI 304 or AISI 316L

- Automatic conveyors with a bar code reader for loading rack identification

- External trolley with integrated roller set for floor-mounted installation in ASI 304 or AISI 316L

- Automatic lifting platform for floor-mounted installation

- Storage systems for racks when not in use, minimizing the number of trolleys and freeing up valuable floor space.

All transfer trolleys are provided with four swivel wheels and a device to lock the structure to the chamber for the loading and to lock the rack to the transfer trolley for transport.

All racks and washing trolleys are provided with a standard validation package that includes:

- Two design reviews for 1 or 2 modular configurations

- Material declaration 2.1

- Weld certificate and WPS

Upon request, standard documentation can be integrated with:

- Material certificate 3.1 for internal cart and trolley according to EN10204

- Complete weld book with welding log and map

- Boroscope inspection and report (including video boroscope): 20% or 100% orbital welding - 100% manual welding

- Dedicated IQ-OQ protocols including coverage/cleaning test with Riboflavin

Autres produits

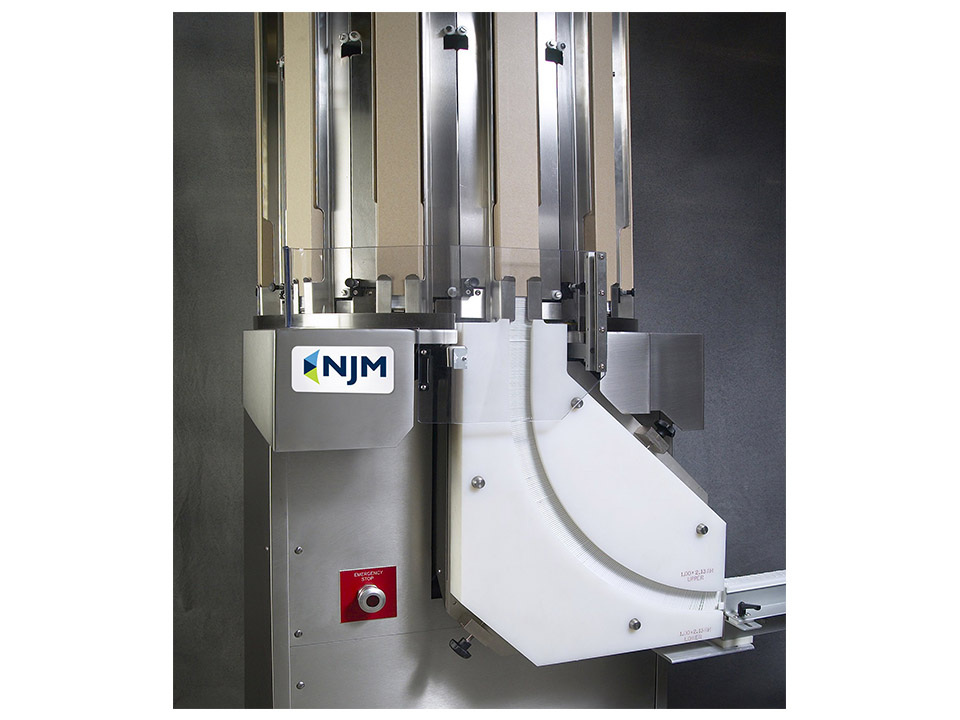

L’alimenteur de contenants UNISORT™ 32 est compact et idéal pour les fabricants de produits pharmaceutiques et de suppléments alimentaires, les aliments, les produits de soin personnel et le conditionnement à façon. Il opère à des vitesses allant jusqu’à 200 unités par minutes. La conception cGMP de l’UNISORT™ facilite la maintenance, améliore l’ergonomie et accélère les changements de produits.

NJM conçoit, fabrique et fournit une gamme complète d'équipements d'emballage, offrant aux clients le soutien d'une source unique, des services d'intégration de ligne clé en main, un support de validation complet, ainsi qu'un service après-vente irréprochable. Nos lignes de production intégrées peuvent inclure des équipements de haute qualité provenant de tiers fabricants de premier plan. Tous les tiers fournisseurs avec lesquels nous travaillons sont soigneusement évalués. En fonction de l'application et des exigences du client, ils sont sélectionnés parmi les membres du PMMI et une sélection de fournisseurs nord-américains et européens. Nous prenons notre rôle d'intégrateur de ligne clé en main très au sérieux. L’équipe NJM intègre l'équipement et assure la communication de première ligne ainsi que tout service après-vente pouvant être requis. De cette façon, nous nous assurons de fournir des systèmes intégrés complets comprenant une grande variété de machines, incluant des systèmes d'impression et de vision.

Le compteur de comprimés Cremer CFS 622 peut accommoder jusqu’à 4 modules de comptage à des vitesses allant jusqu’à 200 bouteilles par minute. Sa conception compacte facilite son intégration à toute ligne de conditionnement, nouvelle ou existante, dans l'industrie pharmaceutique ou nutraceutique.

Avec la série CFI 622, Cremer a établi un nouveau standard pour le comptage et le remplissage en mouvement dans l’industrie pharmaceutique et nutraceutique. Le système de comptage et de remplissage CFI 622 est disponible en deux modèles : CFI 622*6 et CFI 622*8 ayant respectivement jusqu'à 6 ou 8 modules de comptage pour une capacité accrue à des cadences allant jusqu'à 400 bouteilles par minute.

Le CF 1220 est un compteur de comprimés et de capsules à 12 voies avec convoyeur à indexation de bouteilles intégré. Le compteur est disponible en deux configurations : le CF 1220 à 12 voies de produits pour des vitesses allant jusqu'à 50 bouteilles par minute et le CF 1220D à 24 voies de produits pour des vitesses allant jusqu'à 100 bouteilles par minute.

L'élévateur de comprimés TE 20 est doté d'un élévateur magnétique breveté et innovant qui facilite le nettoyage. L'ergonomie est améliorée en permettant aux opérateurs de remplir la trémie de comprimés à une hauteur confortable. L'élévateur soulève ensuite un godet de transport pour alimenter un compteur de comprimés ou une emballeuse à barquette à des vitesses allant jusqu'à 20 000 produits par minute.

L'élévateur à comprimé TE 10 comprend une trémie en acier inoxydable de 10 pi3 (283 litres) élevée par un treuil électrique avec frein de secours. L'ergonomie est améliorée en permettant à l’opérateur de remplir la trémie de comprimés à une hauteur confortable. L'élévateur peut alimenter un compteur de comprimés ou une emballeuse à barquette avec une variété de produits à des vitesses allant jusqu'à 18 000 produits par minute.

Machines de remplissage et de fermeture de flacons pour le traitement de produits liquides, semi-solides et en poudre dans des conditions stériles.

Cet équipement de remplissage et de fermeture de seringues jetables prêtes à l'emploi offre sécurité, hygiène et précision de dosage pour les injections médicales.

Des machines de remplissage et de fermeture pour le traitement de cartouches de verre ou de plastique contenant des produits injectables nécessitant un environnement stérile.

Les seringues jetables prêtes à l’emploi offrent sécurité, hygiène et précision de dosage pour les injections médicales.

Nous proposons des machines de lavage, stérilisation, remplissage et fermeture de bouteilles pour le traitement de produits liquides, semi-solides et en poudre dans des conditions stériles.

L'équipement que nous proposons est une machine compacte de remplissage et de fermeture pour le traitement automatisé de microtubes en plastique, pour liquides ou produits semi-solides.

L'équipement modulaire de remplissage et de fermeture de Dara Pharma traite des sacs flexibles préformés à cavité unique ou multiple, fabriqués en EVA, PVC, PE ou PP, offrant une production allant jusqu'à 3 200 unités par heure. Ces solutions sont conçues conformément aux normes BPF (bonnes pratiques de fabrication) et aux réglementations de la FDA américaine, spécifiquement pour répondre aux besoins des industries pharmaceutique et biotechnologique.

Dara fabrique des équipements automatisés pouvant performer en une seule ligne intégrée.

Dara offre une vaste gamme d’équipement de stérilisation et de dépyrogénation pour le traitement de contenants de verre tels que les fioles, les cartouches et les seringues.

Moduline™ est un nouveau concept de remplissage aseptique à l'intérieur d'un isolateur. Il s'agit d'un isolateur compact, modulaire et de conception unique pour le traitement de flacons, de bouteilles, de seringues ou de cartouches et leur remplissage de liquide ou de poudre dans des conditions stériles.

Freeze dryers for small-scale production aimed at research centers, laboratories, and pharmacies, among others. Dara Pharma showed its tabletop equipment with the SX-50 SpeedFill and SX-100 machines and presented state-of-the-art Fill & Finish solutions.

La cotonneuse automatique CL 110 insère une longueur prédéterminée de coton, de rayonne ou de polyester dans des contenants à un régime pouvant atteindre 110 unités par minute. Sa fabrication robuste vous garantit précision et fiabilité tout au long de sa vie utile. Sa conception peu encombrante vous permet d’intégrer cette unité sans difficulté à vos opérations de conditionnement.

La cotonneuse automatique CL 200 insère une longueur prédéterminée de coton, de rayonne ou de polyester dans des contenants à un régime pouvant atteindre 200 unités par minute. Sa fabrication robuste vous garantit précision et fiabilité tout au long de sa vie utile. Sa conception peu encombrante vous permet d’intégrer cette unité sans difficulté à vos opérations de conditionnement.

Les bouchonneuses en ligne Beltorque® Lite offrent la même haute qualité et la même précision de serrage de bouchons que notre modèle haute vitesse beltorque® BT-IC, à un prix d'entrée de gamme. Grâce à ses courroies synchronisées, ce modèle polyvalent et innovant procède au serrage sans rayer les bouchons. Cette machine à mouvement continu dispose d'un contrôle central pour l'ajustement du serrage et fonctionne à des vitesses allant jusqu'à 150 unités par minute.

Les bouchonneuses en ligne Beltorque® BT-IC sont dotées d'un système de tri et d'alimentation de bouchons à servocommande, ainsi que d’un système de surveillance du couple de serrage en temps réel. Grâce à son système de courroies synchronisées, cette machine polyvalente et novatrice effectue les torsions serrage sans endommager les bouchons. Cette unité en mouvement continu dispose d’un contrôle pour l’ajustement du serrage et peut opérer à un régime de 300 unités par minute.

Les resserreurs en ligne beltorque® offrent par un serrage des bouchons précis et de haute qualité. Grâce à son système de courroies synchronisées, cette machine polyvalente et novatrice effectue le serrage après le scellage par induction sans endommager les bouchons. Cet équipement en mouvement continu est doté d’un contrôle central pour l’ajustement serrage et peut atteindre un régime de 300 unités par minute.

La bouchonneuse en ligne UNICAP 150 est polyvalente et gère une grande variété de récipients à des vitesses pouvant aller jusqu'à 200 unités par minute. Elle permet des changements de produits facilement et rapidement pour un maximum de flexibilité.

Le resserreur RTQ 150 réapplique le serrage approprié au bouchon après le scellage par induction. Il opère à des vitesses allant jusqu'à 200 unités par minute. Cette unité à cadence continue est de fabrication robuste et à longue durée de vie.

La bouchonneuse par vissage électronique de la série CAE de Zalkin est un équipement à la fine pointe de la technologie dotée d’un moteur DC indépendant permettant de gérer le serrage à 100 % à des vitesses allant jusqu'à 600 unités par minute.

Les bouchonneuses automatiques Zalkin de la série CAS traitent toutes les variétés de bouchons pour une multitude d'industries à une vitesse allant jusqu'à 1200 bouteilles par minute à l’aide de têtes de serrage à embrayage magnétique.

L'étiqueteuse par enroulement MINICOLT™ 120 est abordable, compacte et précise. Elle applique des étiquettes autocollantes à des contenants ronds à des vitesses allant jusqu'à 100 unités par minute.

L'étiqueteuse à servomoteur TROTTER™ gère une large gamme de contenants ronds et applique des étiquettes autocollantes à des vitesses allant jusqu'à 150 unités par minute. Cette étiqueteuse est disponible en deux configurations de contrôle : le TROTTER™ par enroulement 126 avec servomoteur et commandes PLC Allen‑Bradley® et le TROTTER™ par enroulement 127 avec servomoteur et commandes B&R.

L'étiqueteuse à servomoteur TROTTER™ est très polyvalente et gère une large gamme de contenants ronds, carrés, rectangulaires ou ovales et applique des étiquettes autocollantes par enroulement, à l’avant et l’arrière ou multicôtés à des vitesses allant jusqu'à 120 unités par minute. Cette étiqueteuse est disponible en deux configurations de contrôle : le TROTTER™ par enroulement 126 avec servomoteur et commandes PLC Allen‑Bradley® et le TROTTER™ par enroulement 127 avec servomoteur et commandes B&R.D55

L’étiqueteuse à servocommandes BRONCO® est très polyvalente et gère une large gamme de contenants ronds, carrés, rectangulaires ou ovales et applique des étiquettes autocollantes par enroulement, à l’avant et l’arrière ou multicôtés à des vitesses allant jusqu'à 200 unités par minute.

L’étiqueteuse de scellés inviolables BRONCO® 130 TE est une machine à servocommande à châssis ouvert capable de gérer une large gamme de cartons et d'étiquettes à des vitesses allant jusqu'à 200 cartons par minute.

Cette étiqueteuse peut gérer à la fois des flacons et des seringues ou être dédiée à l’un des deux. Elle est compacte et dotée d’un tourillon à étoile pour un contrôle optimal de l'inclinaison et la manipulation efficace des flacons, seringues et autres emballages petits ou instables tels que les ampoules, les cartouches, les tubes à centrifuge et les auto-injecteurs. Elle atteint des vitesses de 250 flacons et de 200 seringues par minute. Une option d'orientation des emballages permet l’application d'étiquettes spécifiques, par exemple sur les conteneurs à bride ou à graduation, à des vitesses allant jusqu'à 100 unités par minute.

L'étiqueteuse AUTOCOLT™ 326 IV offre le nec plus ultra en matière de polyvalence et la précision de l'étiquetage à servocommande. Il gère une variété de contenants et de configurations d'étiquettes à des vitesses allant jusqu'à 300 unités par minute. Cette étiqueteuse peut être équipée d'une grande variété d'options, incluant l’alimentateur et l’applicateur de notices sur le dessus ou les côtés AUTO-SERT®.

L’étiqueteuse d’autocollantes AUTOCOLT 326 IV TRUNNION dispose d’un système d’entrainement à rouleaux à servocommandes pour un haut niveau de précision et un contrôle optimal de l'inclinaison des étiquettes à des vitesses allant jusqu'à 400 unités par minute.

La tête étiqueteuse 251 est montée sur un support portatif vous permettant de déplacer celle-ci d’un endroit à l’autre sans difficulté, selon ce qui est requis pour maximiser la productivité de votre usine. Cette machine à servocommandes peut effectuer un étiquetage sur le dessus, les côtés ou personnalisé selon vos besoins, à des vitesses allant jusqu’à 200 unités par minute.

Applicateur de notices à colle chaude AUTO-SERT®277 peut être configuré pour appliquer des notices sur le dessus (277 TOPSERT) ou les côtés (277 SIDESERT), selon les besoins spécifiques de l’étiquetage pharmaceutique à des vitesses atteignant 280 unités par minute. NJM propose également un alimentateur de notices - standard sur le 277 TOPSERT et offert en option sur le 277 SIDESERT - pour une durée de fonctionnement prolongée et une ergonomie améliorée.

Conçu en acier inoxydable, l’alimentateur de notices 276 Carousel augmente considérablement la capacité de stockage des notices, permettent aux entreprises de conditionnement pharmaceutique de réduire leurs coûts de main-d'œuvre et d’améliorer l'ergonomie de travail. L’alimentateur de notices 276 Carousel gère une vaste gamme de notices et s’intègre facilement à tout équipement d’application de notices sur le dessus ou les côtés, à des vitesses allant jusqu'à 250 unités par minute.

Cette étiqueteuse polyvalente permet l’impression et l’application verticale et horizontale d’étiquettes sur des paquets et des caisses à des vitesses allant jusqu'à 60 unités par minute.

La solution de repérage et de sérialisation de bouteilles est conçue pour vous aider à respecter les normes règlementaires en matière de sérialisation d'étiquettes et d'agrégation de contenants tout en améliorant l'efficacité de votre ligne à des vitesses allant jusqu'à 250 unités par minute.

L’encaisseuse Cumulus™ SLPP-15 est un système semi-manuel conçu pour automatiser la production en fin de ligne. Cette machine modulaire est peu encombrante et prête à l’intégration de caméras pour faciliter l'agrégation et la sérialisation à des vitesses allant jusqu’à 5 caisses par minutes avec un seul opérateur et 10 caisses par minutes avec deux opérateurs.

Chez NJM, notre service d'intégration de ligne clé en main commence bien avant l'achat, grâce à nos départements d'ingénierie et de vente dédiés. Une évaluation de l'espace au sol disponible, des exigences utilisateurs et des composantes d'emballage requises permet à notre équipe de fournir des agencements d’équipements personnalisés qui intègrent des machines ProMach, de tierces parties et même existantes, pour vous fournir des solutions innovantes et rentables. D’une vitesse de quelques unités à 400 unités par minute, l'intégration d'équipements de remplissage à basse et haute vitesse est une spécialité de NJM depuis plus de trois décennies.

En intégrant une tête de détection de métaux à un convoyeur surélevé NJM, nous avons éliminé l’étape du transfert de bouteilles. Le CMD offre des performances supérieures à des vitesses allant jusqu'à 250 unités par minute. Sa conception permettant la capture de comprimés non conformes aide les fabricants et les emballeurs sous contrat à garantir la sécurité des produits et à éviter les rappels de produits coûteux.

Nous proposons une gamme complète de systèmes d'inspection qui identifient et rejettent automatiquement les produits défectueux de la ligne d'emballage afin de réduire les reprises et d'assurer une qualité finale conforme aux spécifications. Les systèmes d'inspection autonomes NJM comprennent la détection de bouteilles tombées/à l'envers, ainsi que l’inspection de produits, de coton, de bouchons et d'étiquettes.

Construits en acier inoxydable, les convoyeurs standards NJM sont dotés d'une plateforme sanitaire surélevée et d'une chaîne de table Delrin de 114 mm (4,5 po) avec moteur d’entraînement à courant alternatif. De conception modulaire, ils sont disponibles en différentes longueurs pour répondre à vos exigences d’aménagement actuelles ou futures.

Les convoyeurs dotés de système de contre piégeage (Tablet Entrapment Free - TEF) NJM sont conçus pour les fabricants de produits pharmaceutiques et nutraceutiques, ainsi que le conditionnement à façon. Sa conception se conforme aux exigences cGMP les plus strictes. Grâce au dégagement rapide de la chaîne de table et à son éclairage DEL intégré, ce convoyeur facilite l’inspection des produits emprisonnés.

Les tables d’accumulation sont disponibles en plusieurs grandeurs et types, incluant convoyeurs bidirectionnels ou circulaires, permettant de répondre aux besoins spécifiques de toutes les applications et de maximiser l’efficacité de la ligne de production. Elles aident à créer une zone tampon avant la station de resserrage pour permettre le refroidissement des bouchons. Elles permettent aussi aux opérateurs de changer les rouleaux d’étiquettes sur l’étiqueteuse sans arrêter la ligne.

Les conduits en acier inoxydable intègrent les fils d'alimentation électrique et de commande et les tubes pneumatiques flexibles qui distribuent l’énergie et l'air comprimé aux machines selon les besoins. Un boîtier électrique stratégiquement situé et combiné aux conduits permet la centralisation des services d'alimentation et d'air pour une distribution efficace à l'ensemble de la ligne de conditionnement. Cette solution complète se traduit par une ligne entièrement conforme aux normes cGMP.

NJM offre une assistance complète en matière de validation et de conformité FDA ou GAMP 5 pour une machine individuelle ou une ligne entière.

ZPI, une marque ProMach, développe et prend en charge les systèmes logiciels d'amélioration de la performance des processus d’emballage de produits. Ces solutions logicielles permettent la surveillance et la collecte de données relatives à l’efficacité globale de l’équipement de la ligne (OEE), à la sérialisation et au suivi, ainsi que la maintenance préventive.

Les encartonneuses Serpa de notre partenaire ProMach Pharma sont compactes et permettent d’économiser l'espace dans votre installation tout en offrant les grands atouts pour lesquels Serpa est reconnue comme la conception à balcon ouvert, la durabilité, les changements rapides et la facilité d’entretien.

Les encaisseuses Serpa de notre partenaire ProMach Pharma présentent une conception avec balcon ouvert permettant un accès complet aux produits. De plus, toutes les encaisseuses et emballeuses à barquette Serpa sont équipées d’un système d’évacuation rapide des caisses. Cette fonctionnalité importante permet d'éliminer facilement les caisses problématiques, maximisant ainsi l’opération de la machine.

En tant qu'intégrateur de système agréé FANUC America, notre partenaire ProMach Pharma, Serpa, a étendu sa gamme de palettiseurs robotisés à trois modèles différents : cellule simple, cellule double et automatique. Tous les palettiseurs robotisés Serpa sont construits selon des normes rigides et robustes pour assurer une disponibilité maximale et une maintenance facile.

Partenaire ProMach Pharma, Pharmaworks dispose d'une vaste gamme d’emballeuses barquette à la fine pointe de la technologie pour répondre aux besoins de tous les types d'emballage barquette. Du BlisterMate semi-automatique à la machine TF3 pouvant produire 300 barquettes par minute, aucune application n'est trop complexe ou trop simple.

The AVD Series combines all the features of a Pharma Grade Saturated steam sterilizer with the capability of performing bio-decontamination cycles using VH2O2.

The AMS Series of Pharmaceutical Grade Steam-Air Mixture sterilizers is a range of autoclaves designed for terminal sterilization using steam air mixture technology.

Steelco’s range autoclaves using superheated water are for the terminal sterilization of injectable solutions.

Steelco designs and manufactures a wide range of Class 100 static depyrogenation sterilizers (ISO 14644-1 class 5) to meet the most challenging pharmaceutical requirements.

Thanks to a long experience within the pharmaceutical, nutraceutical, cosmetic, and food industries, Steelco offers a wide range of hot air static dryers to meet the most challenging market requirements.

Sterile continuity is the vision. The SPE Series is ideal for treating closures for containers normally used in the pharmaceutical industry, where continuous sterility has to be maintained between different phases.

The DHP Series of Grade Decontamination air Lock is manufactured to provide a complete turnkey solution for the bio-decontamination of heat-sensitive equipment.

The AGS Series of sterilizers using Ethylene Oxide represents the best relationship between engineering and quality price, operating running costs, and, most important, the safety of the system and operators.