Visit Us at Interphex in Booth 2353

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreLiquid Filling & Closing / Aseptic Processing

NJM's partner Dara Pharma is a leader in pharma aseptic processing

Dara Pharma provides pharmaceutical packaging machines to the pharmaceutical, biotechnology and cosmetics industries with the most technologically advanced equipment on the market, contributing to the improvement of people's well-being and quality of life.

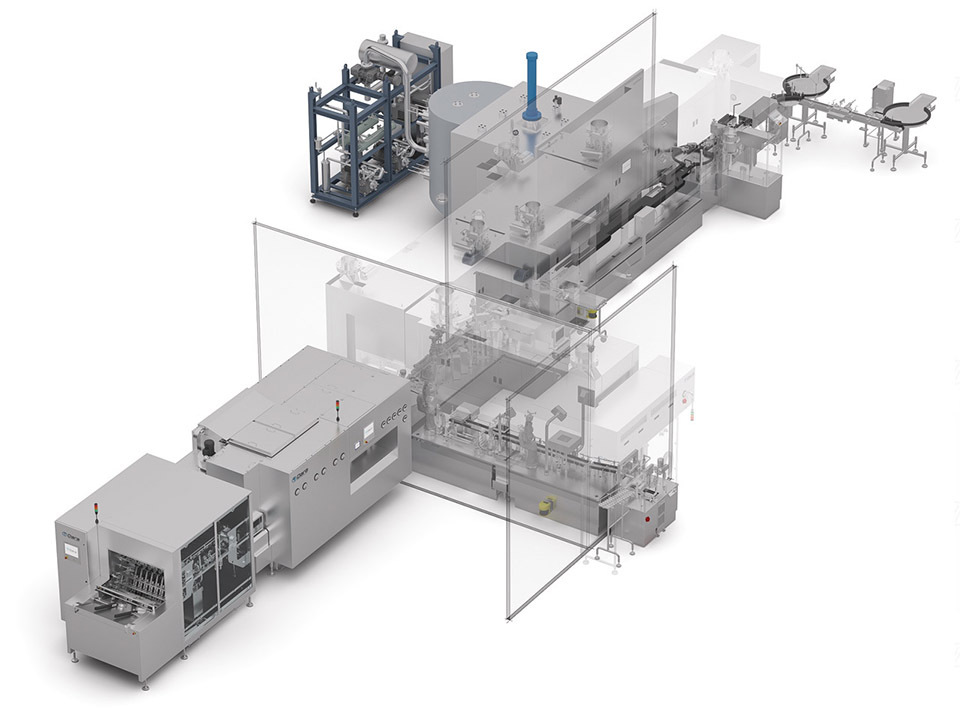

Dara Pharmaceutical designs, develops, and manufactures packaging equipment for washing, sterilizing, filling, freeze-drying, and closing machines for vials, bottles, syringes, cartridges, and IV Bags to process liquid, semi-solid products, and powders in sterile conditions.

NJM is the exclusive sales agent for Dara Pharma & Coolvacuum in the USA and Canada. Click here for more info on Dara Pharmaceutical.

Dara Pharma provides the pharmaceutical industry compact machines for the automatic filling and closing of plastic and glass vials, for producing liquid, semi-solid and powder products, in sterile areas or clean rooms. These aseptic solutions are based on a modular design, which is one of Dara Pharma’s distinctive technological advantages, as it allows every machine to be configured by adapting it to every client’s requirement, offering as well very competitive costs and delivery times. Apart from this, it is worth highlighting that Dara Pharma’s filling and closing solutions, named “Combi”, have revolutionized the aseptic packaging machinery industry since they are able to process multiple vial formats in different sizes and shapes, in the same unit.

Single-use syringes is a format that offers the highest safety, hygiene, and dosing accuracy for pharmaceutical applications such as medical injections. Beyond filling and closing the syringes, it is necessary to equip and assemble them with the aspects that the end user will need for correctly administrating the dose, and for their own safety. Our ASL (Assembly Syringe Line) machines have been designed for the assembly and labeling of glass and plastic syringes, and incorporate all the required technologies for plunger shaft positioning, syringe body labeling, backstop assembly system, insertion of safety devices and, if necessary, labeling of safety devices. These pieces of Pen Device and Syringe Assembly equipment have been developed for optimal filling and operation in clean rooms, complying with cGMP and US FDA standards, in compliance with the requirements of the pharmaceutical industry.

Cartridges are used all over the world in specialties like emergency medicine, diabetes, and dentistry, establishing themselves as suitable for both biologic and non-biologic medications. They now provide patients with a wider selection of needs and drug administration methods such as pens, auto-injectors, and consumables, providing more freedom.

Dara Pharma has long been investing in the development of new RTU (Ready-to-use) technologies that enable the processing of aseptic products in a versatile, adaptable, and compact way, reducing energy consumption and the space needed on site to achieve flexibility.

Dara Pharma offers different filling, closing, and labeling equipment and complete lines, for which dosage capacity goes from 1 ml to 1,050 ml, and even up to 20,000 ml in cases of specialized equipment for large capacity volumes, with production up to 24,000 uph.

Microtubes have proven to be safe and effective containers countless times since they were first introduced into the pharmaceutical market.

Dara Pharma’s modular filling and closing equipment processes single or multi-cavity preformed flexible bags made of EVA, PVC, PE, or PP, offering a production of up to 3,200 uph. These solutions are designed in accordance with cGMP and US-FDA regulations.

Customers will be able to tackle any challenge presented by the dosing of their products, no matter how specific they are: from eye drops to nasal sprays, including UDB/BDS, pen devices, etc.

Dara Pharma washing machines, whether in linear or rotary configuration, have been developed for maximum efficiency, minimal consumption, and maximum versatility. With Dara Pharma's wide selection of modular sterilization and depyrogenation systems, glass containers such vials, ampoules, cartridges, and syringes can be processed quickly and continuously.

The growing concern for product and operator protection, and the increasingly broad pharmaceutical regulatory framework make it essential to have available containment systems in conjunction with production equipment, should that be necessary.

Dara Pharma and Coolvacuum combine their expertise and in-depth knowledge to provide cutting-edge freeze-drying technology and solutions.

The ongoing evolution of medication and creation of new drugs, as well as a proliferation of dosage techniques, has led the pharmaceutical industry to invest in complex but reliable production lines, with the main purpose being the capable adaption to different and specific needs.